High-Speed Bolt Nuts Routing

Project Overview

As part of the Penn State ME 440W Capstone, the Bolt Nuts team developed a routing device capable of sorting 400 bolts per minute. Designed to work with PennEngineering’s National 25HS Cold Header machine, the device aimed to improve production efficiency and lower operational costs.

Sponsor: PennEngineering2023

Technical Contributions

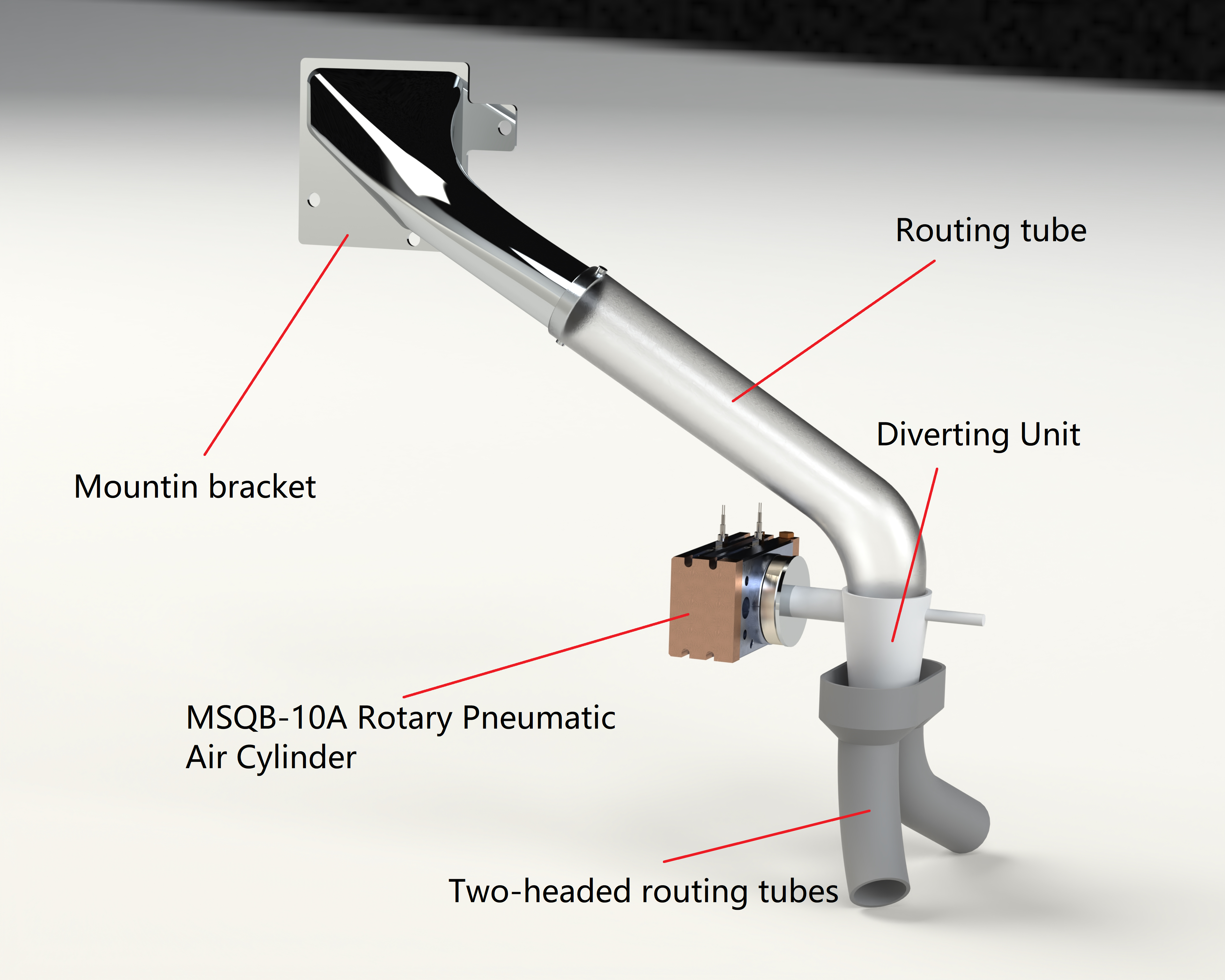

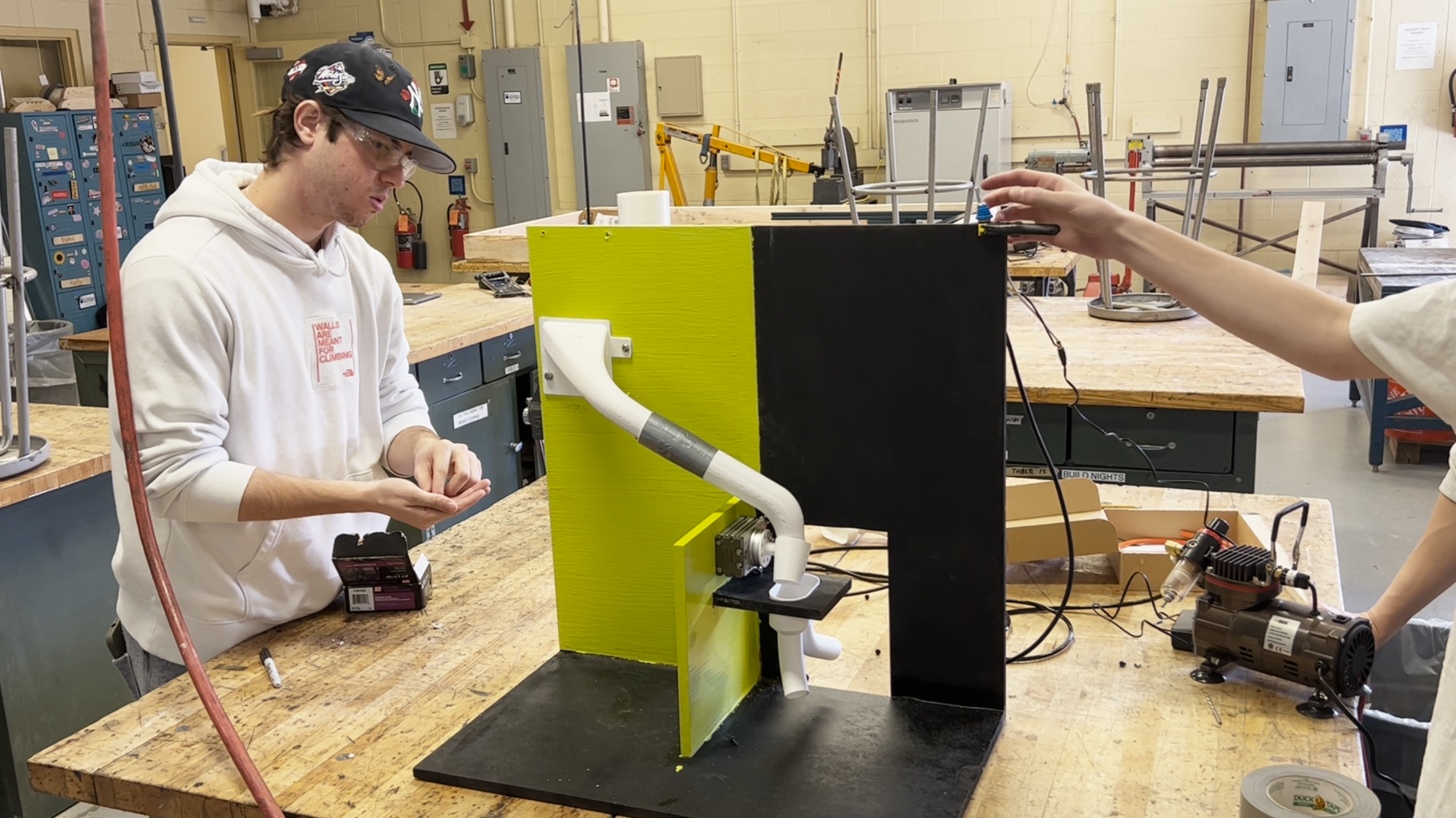

Design and Prototyping: During the project, I was involved as the project manager, cooperating and communicating with our sponsor and leading the entire team. My focus was making sure everything would integrate smoothly with the Cold Header machine and work right out of the gate. I was also the main designer of the project, I designed, engineered, and 3D printed major components using SolidWorks and installed electrical and pneumatic systems of the prototypes, ensuring the system integrity and functionality.

I was also responsible for tackling the dimensions of all systems, as our project included numerous components. It was important to ensure that all parts would fit together seamlessly. Additionally, I generated a detailed video using SolidWorks to visually demonstrate how the design functions, enhancing our presentation and providing a clear, dynamic representation of our prototype in action. Once we finished our prototype, I put together a video using Adobe Premiere Pro to show off how we went from concept to functional prototype.Impact and Outcomes

By the end of the project, we delivered exactly what PennEngineering needed. Our device sped up the bolt sorting process, reduced manual labor, and minimized maintenance hassles, proving itself as a cost-effective upgrade for their production line.

Find out more about this project from the Penn State SP 23 Capstone projects